What Are the Options to Reduce Aviation Pollution?

For every kilogram of jet fuel burnt, 3.16 kilograms of CO2 are produced. Why so much? Because oxygen is heavy and when it blends with the carbon in the fuel it adds on its mass.

In a flight from San Francisco to New York, a plane will use about 18,000 kg of fuel, releasing the incredible amount of 55,800 kg of CO2. To put that in perspective, re-absorbing that CO2 can take about one year and 2,200 trees.

Such pollution is not in line with current sustainability goals needed to slow down climate change. But even if it was, the more scarce and expensive petroleum will eventually call for a change.

What to do then?

Diesel, Kerosene and Gasoline

The fuel used by commercial planes is based on petroleum derivatives. Petroleum is a hydrocarbon, meaning that it's made up of Carbon (C) and Hydrogen (H) atoms that form molecules of different sizes.

Methane (CH4), with just one carbon atom in each molecule, is one of the lightest hydrocarbons. Engine fuels derived from petroleum are a mix of heavier hydrocarbons. The heaviest mix is in is diesel, then kerosene and the lightest is gasoline. Each fuel has properties that makes it more or less suitable for different engines. For example, diesel can autoignite when compressed, whereas gasoline needs a spark to trigger the combustion.

Jet A-1 fuels

Most commercial planes use the Jet A-1 fuel, a kerosene based fuel. There are several advantages of kerosene for planes: lower freezing point than diesel, higher power-to-weight ratio than diesel, and a higher flashing point than gasoline.

Like other engine fuels, combustion of kerosene produces CO2, NOx, SOx, and carbon nano particles from incomplete combustion known as soot. All of these particles are known to affect our health and accelerate global warming, but recently, a new problem was discovered.

Contrails (short for condensation trails) are the white trails that from behind planes when water vapor freezes around the small exhaust particles. Water vapor is always a product of hydrocarbon combustion, and example for Octane combustion is:

2C8H18 + 25O2 → 16CO2 + 18H20

In a humid day, contrails can persist for many hours and develop into clouds that are indistinguishable from those occurring naturally. This was assumed to be harmless, but a deeper understanding in radiative forcing revealed that they block part of the heat released by the earth during the night, therefore increasing the global warming damage.

Contrails cover about 0.1% of the atmosphere, and it is estimated that they have even higher global warming potential than the CO2, releases. It is currently a hot topic whether planes should take alternative routes to avoid high humidity regions to mitigate this effect.

Sustainable Aviation Fuels (SAFs)

SAFs are biofuels, meaning that they are produced from recently dead organic matter rather than petroleum. So SAF is Kerosene, and planes using it will exhaust the same CO2 as Jet A-1 fuel. The benefit is that the exhausted CO2 can be re-captured by growing a new batch of plants, therefore leading to a lower net CO2 release.

As of today, there have been over 450,000 flights that took-off using SAFs fuels. The International Air Transport Association (IATA) claims that, for those flights, SAFs were able to reduce emissions by 80%. Despite these promising numbers, there are some challenges in the way of biofuels.

Most importantly, SAFs will also produce contrails, so even if they help cutting the CO2 emissions, half of the problem will continue.

Another problem is land use: biofuels needed to grow many plants, and fast. Deforestation caused by sugarcane and corn plantations (the main sources for biofuels) is already a problem in the tropics. It also triggers a battle between “food vs fuel”, plus the quick growth cycles require intensive soil use with pesticides and fertilizers.

According to a recent study, if 10% of the world energy was supplied by biofuels, it would occupy at least 11.4% of the worlds arable land, which is roughly the entire arable land of the United States.

Despite the challenges, biofuels might serve as a bridge between the highly polluting fuels that are used today and the cleaner propulsion systems that are yet to come.

Batteries or Hydrogen?

If neither Jet A-1 or SAFs fuels are sustainable in the long run, batteries and Hydrogen are the next available options.

Hydrogen has already lost the battle for electric cars. It's low efficiency in production, distribution and conversion to electricity are clear disadvantages. The so called round-trip-efficiency quantifies this cycle, giving a 30% efficiency for Hydrogen fuel cells and a 83% for Li-ion batteries.

But there is still hope for Hydrogen. At least, Airbus is now working on their ZEROe engine which will run only in Hydrogen. We will see where it goes.

Batteries are great in efficiency, but the main limitation of using them in planes is the power density; that is, the amount of power delivered per kilo, usually measured in units of Watt-hour per kilo (Wh/kg). Intuitively, planes demand high power density: powerful batteries that weight very little. But how much exactly?

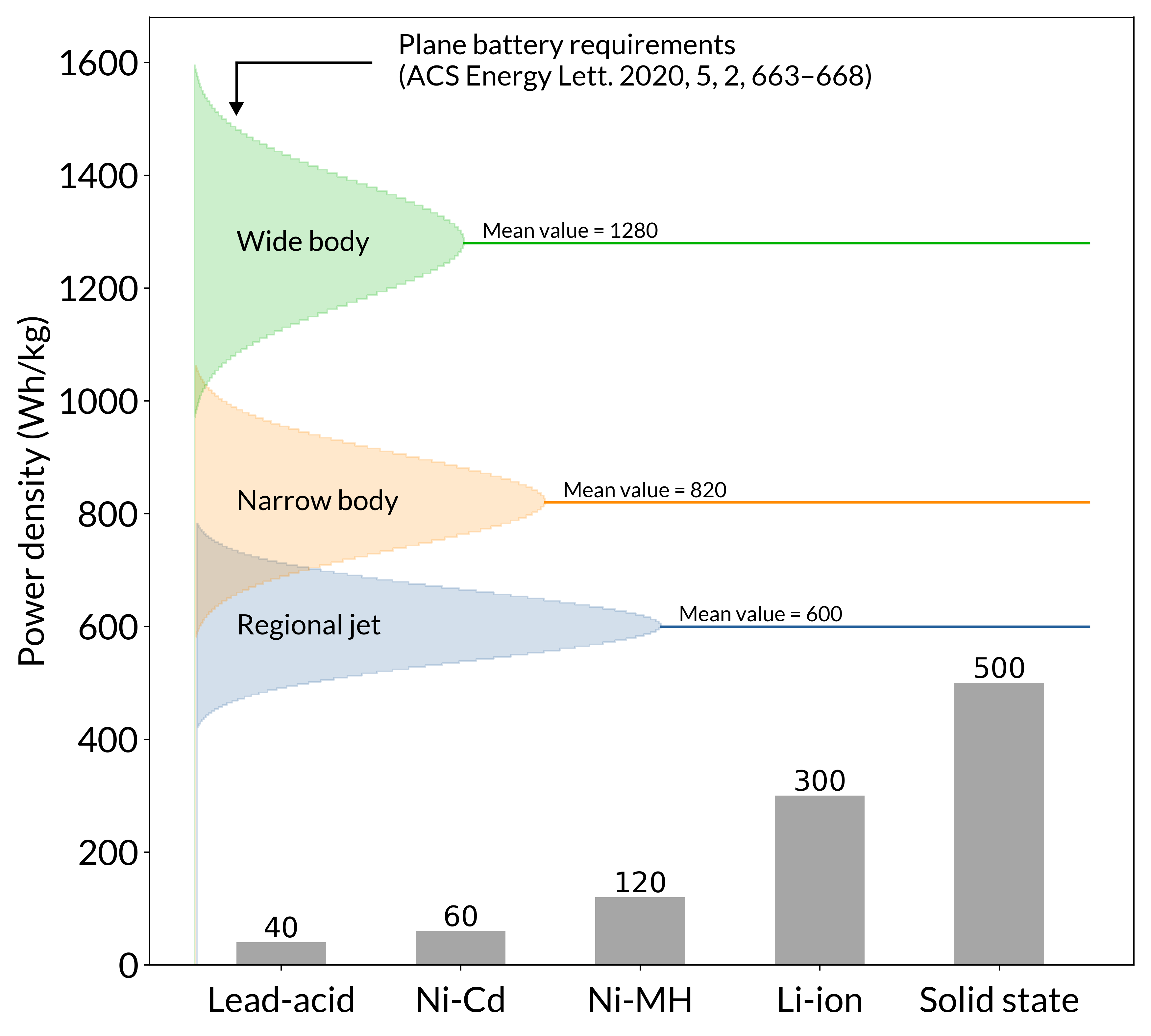

The power density requirements vary depending on the plane weight, geometry, takeoff power and intended distance to travel. In a recent study, all these parameters were combined to obtain expected power density distributions required by different planes. The results were as follows:

Lithium-ion batteries

Battery technology has been improving continuously during the past decades. The initial lead-acid batteries had a maximum power density of just 40 Wh/kg, and the current Lithium-ion batteries found in Tesla cars can reach a peak of about 300 Wh/kg. Amprius Technologies was able to build a 450 Wh/kg battery for satellites, but it remains to be seen if they can mass produce it at a reasonable cost. Even with that, these batteries will likely fall below the requirements of the regional jets.

But there is an added problem: the electrolyte fluid inside the batteries (the Lithium ions) is extremely flammable, a problem for planes given the large accelerations and temperature changes that happen during a flight.

Solid State batteries

Toyota holds more patents on batteries than any other company in the world, and they plan to be the first in releasing a car with solid state batteries in 2025. According to the statement, it will double the range of a car running on Li-ion batteries.

As the name indicates, solid state batteries replace the fluid electrolyte is with a solid one. The energy density of the solid is larger than the previous liquid, leading to a reduction in volume and weight. Other benefits are that the risks of leakage or fire are entirely erased, and that these batteries can charge much faster than the Li-ion ones.

Recent experiments done at NASA showed a performance of 500 Wh/kg for their solid-state batteries. We don't know what will be upper limit for solid-state batteries, but Li-ion started with a power density of about 100 in 2010, and now they have almost tippled.

Despite these good numbers, it is not expected that solid state batteries will be able to reach the needs of long-range flights. So these will probably need to wait for the batteries to come after solid state ones.

Are airlines investing in batteries?

The new battery designs are gathering attention in the aviation industry. In December 2022, Air New Zealand signed a letter or intent with Eviation to purchase 23 of their Alice model, an all-electric regional plane using Lithium-polymer batteries. There is already one Alice prototype, and its first successful takeoff was in September 2022.

Air Canada has invested 5 M dollars in the development of the all-electric ES-30, and has also signed an intent to purchase 30 of them. The ES-30 is manufactured in Sweden by a cooperation between Heart Aerospace and SAAB and plans to use Lithium-ion batteries.

The Nordic Network for Electric Aviation is also on the move, with over 11 different startups and airlines investing in electric flights.

This is just the beginning. We will probably see many startups rise and fall during the process, but if the current Lithium-ion technology cannot make it for regional flights, solid state batteries will likely step in and provide the breakthrough that aviation very much needs.